Watch and Learn

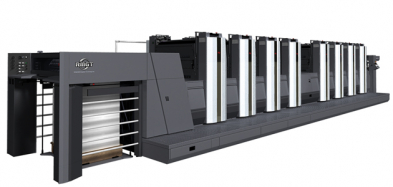

Introducing the new

RMGT 970 Series

Learn More

Automate Your Shop with Horizon Bindery Equipment

New LST Digital Cutter at TECHEXPO 2020

Plockmatic Morgana Leaders in Digital Finishing

NEW EQUIPMENT